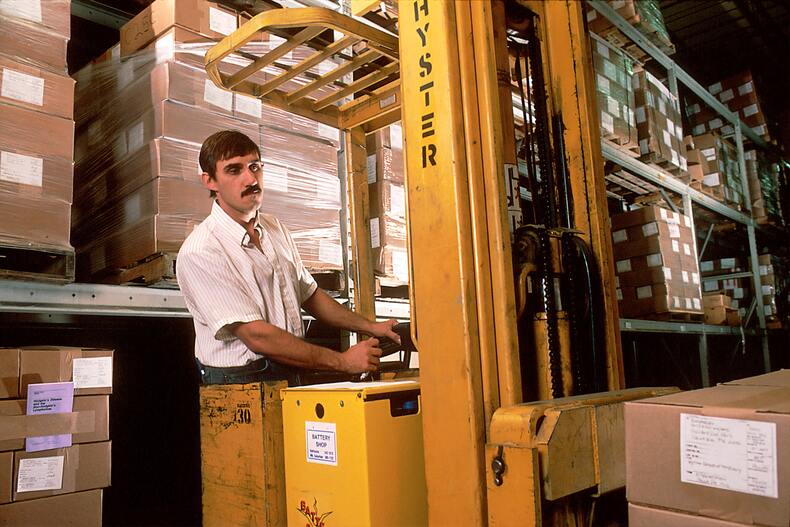

Forklift Servicing and Maintenance

A good forklift is an important piece of equipment in many industries. Without a working forklift, many jobs become impossible to perform correctly. Like any good tool, your company’s Taylor forklift requires regular maintenance and part replacement. Forklifts perform heavy-duty hard work daily and this results in wear on various parts. Much like an automobile or tractor, a forklift needs regular part replacement and servicing to operate at its best.

Regular Service Items

- Hose Replacement: your forklift contains various rubber hoses such as a hose for power steering, the reservoir tank, hydraulics, and others. Other rubber parts need regular replacing, such as the wheel and master cylinders. In general, these rubber parts should be replaced every 4,000 hours of use or every two years.

- The Forklift Lift Chain: another part of your forklift that sees heavy use is the lift chain. In addition to regular maintenance, your lift chain should be replaced every three years or after 6,000 hours of use. Regular inspections can tell you if the lift chain is in good condition. Signs you need servicing include sagging and the chain becoming elongated.

- Problems With The Steering: a lack of responsiveness and odd noises could be a sign of a steering issue. A steering issue can have several underlying causes. These causes can include hydraulic problems, damaged gears, loose pressure valves, tires that are not correctly aligned, and low steering fluid levels. You should also check your steering fluid to make sure it isn’t old or contaminated. Thickened or discolored fluid is a sign you need to completely replace your steering fluid.

- The Forklift Doesn’t Start: when a forklift doesn’t turn on, the issue likely relates to the power source. An electric forklift could have a weakened, damaged, or dead battery. Combustion engine forklifts should have the fuel checked for low levels, leaks, or age. Other things to check include the oil levels and coolant levels, as low fluid levels can cause some forklifts not to start.

Also Read: Shipping To Amazon FBA Rapid Express Freight

Other Common Issues

While many service items do require professional servicing, general maintenance items can often be handled without professional assistance. However, if you feel you lack the skills or tools to perform any maintenance item, you should contact a professional to prevent possible damage or ineffective service or repairs to your forklifts. Common service items include.

- Replacing filters when they become clogged prevents possible damage to the engine, intake, and other systems.

- Fluid refills can also be handled quickly. If the existing fluid is still in good condition and is simply low a refill with fresh fluid is often all that is required.

- Visual inspections can quickly detect any issues that need addressing. This includes problems or repair needs you can solve yourself or ones that require a professional.

- Finally, be sure to check your batteries to make sure they are properly charged and recharge them as needed if possible. Old batteries that are not charging correctly should be replaced as soon as possible.

Final Thoughts

Regular servicing of your forklifts not only keeps them in top working condition, it can also help them last longer. By ignoring servicing needs and not replacing old parts, you greatly increase the odds of a total breakdown and expensive repairs in the future. Being attentive to servicing needs can save you money over the long term.